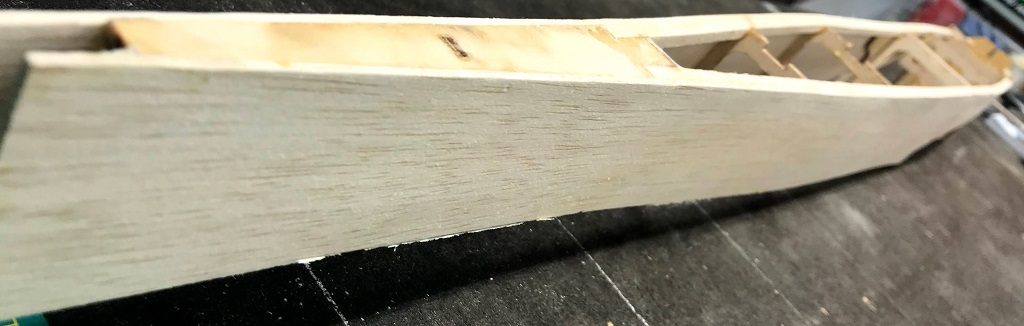

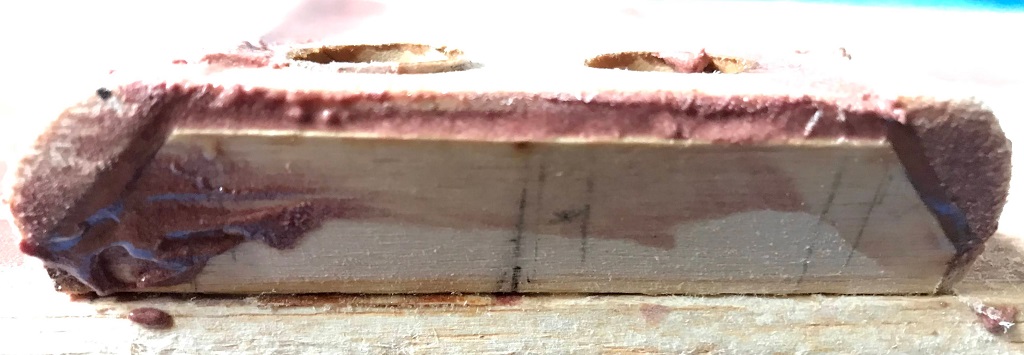

Building Aero 3D Day 65: Fuselage Sanding

It is bitter sweet, though it was great to get back working on my plane last night it also means the end of another flying season. Granted there wasn’t much of a flying season for me, as had more important things to do… namely becoming a father for the first time. The session started with […]

Building Aero 3D Day 65: Fuselage Sanding Read More »