Building Seamater Day 44: Gluing Hinges / Control Surfaces

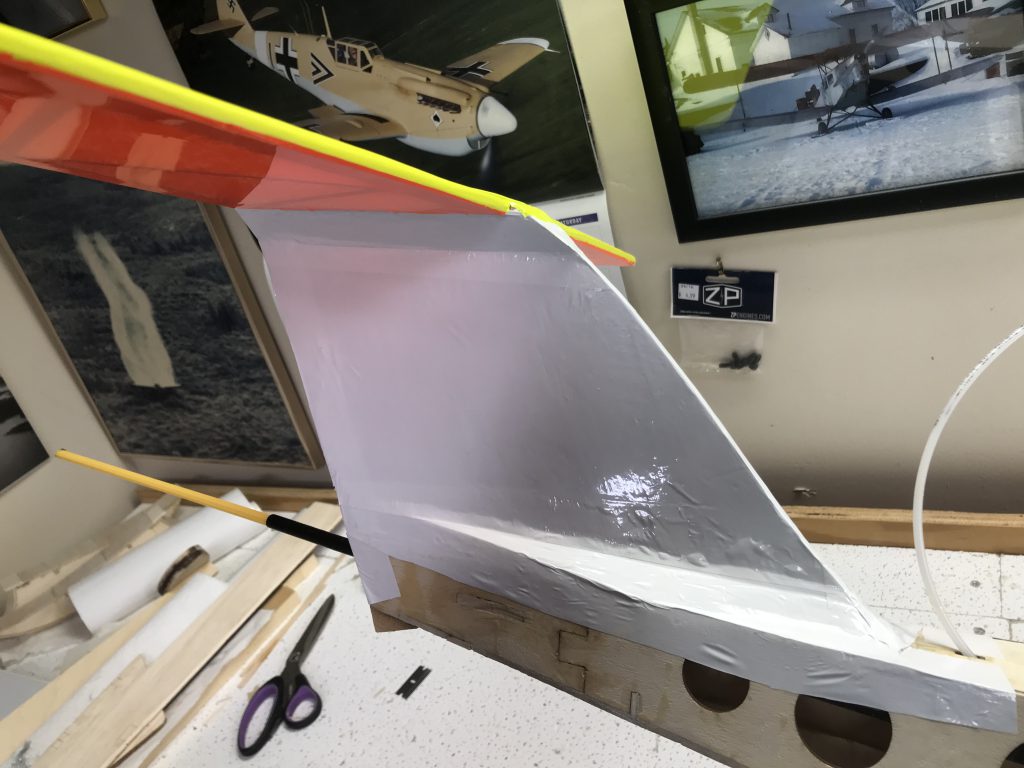

On Dec. 18th I could really start to see things coming together as I worked on putting the bondages for all the control surfaces into place. The first step was to ensure the hinges fit into the slots off the main surfaces (wing for ailerons and fin & stabilizer for the rudder & elevator respectively). […]

Building Seamater Day 44: Gluing Hinges / Control Surfaces Read More »