Building Aero 3D Day 10: Second Side Sheeted

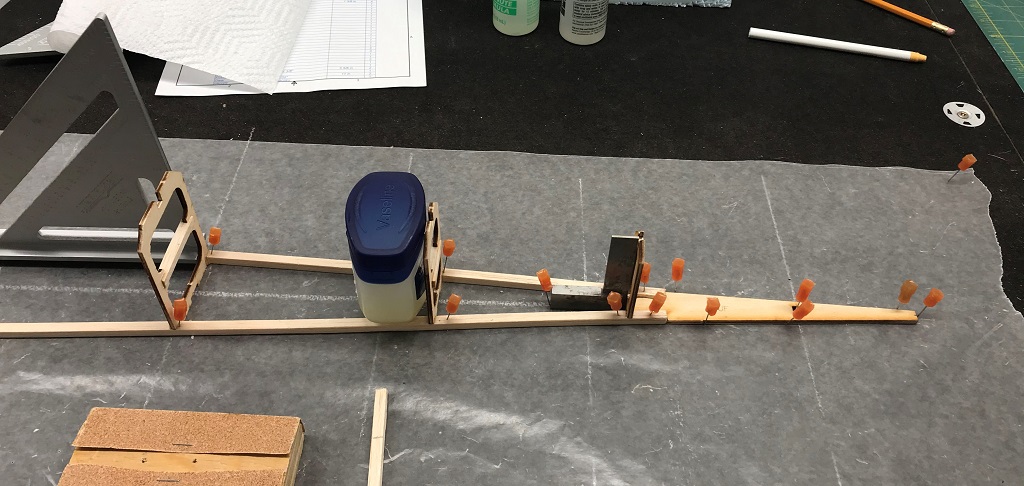

Today Peter and I made more progress on the sides of the aircraft. The day started by removing all the clamps from the previous session and seeing how well everything stuck. Overall we were very impressed with how the wood working glue held everything together. Using this glue is new to us. We then trimmed […]

Building Aero 3D Day 10: Second Side Sheeted Read More »