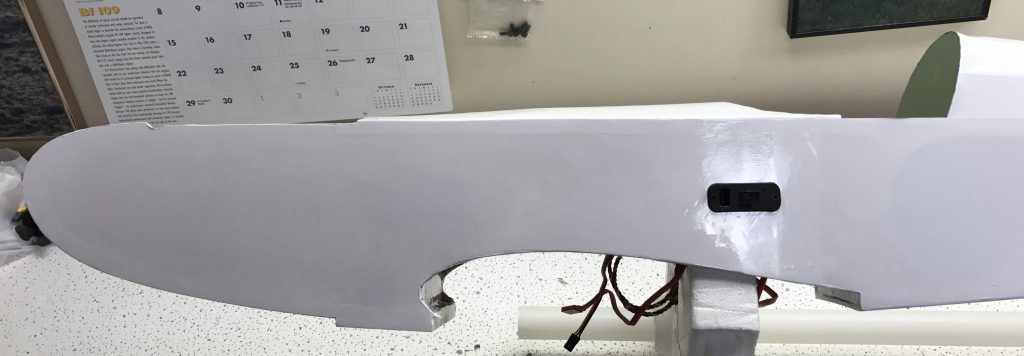

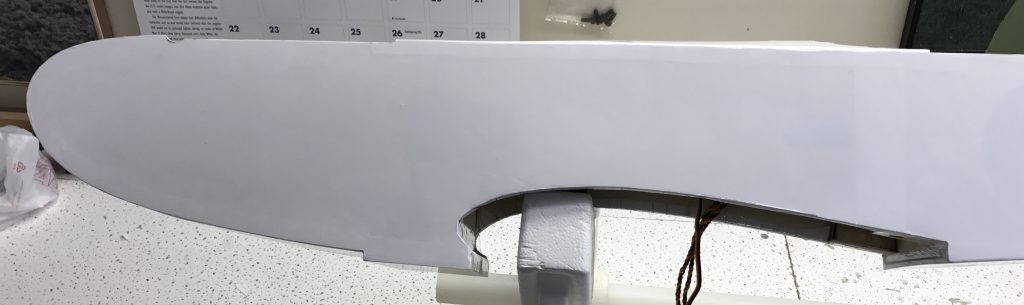

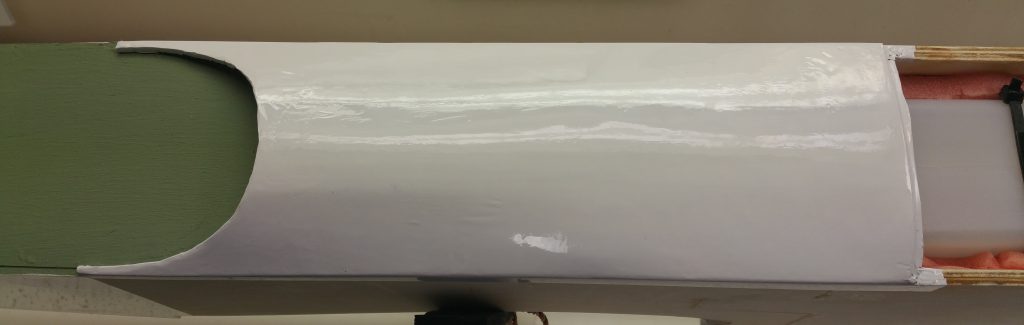

Building 4 Star 60 Day 44: Canopy Cut & Pilot Installed

Tuesday was on the shorter side (1.5hrs) but accomplished the two goals that were set out for the evening, cutting the canopy and securing the pilot in place. The first task was to cut the canopy. This may sound like a simple task, but the thing to remember is that I only have one and […]

Building 4 Star 60 Day 44: Canopy Cut & Pilot Installed Read More »