Building 4 Star 60 Day 37: Covering, Fuel Tank and Rudder Hinged

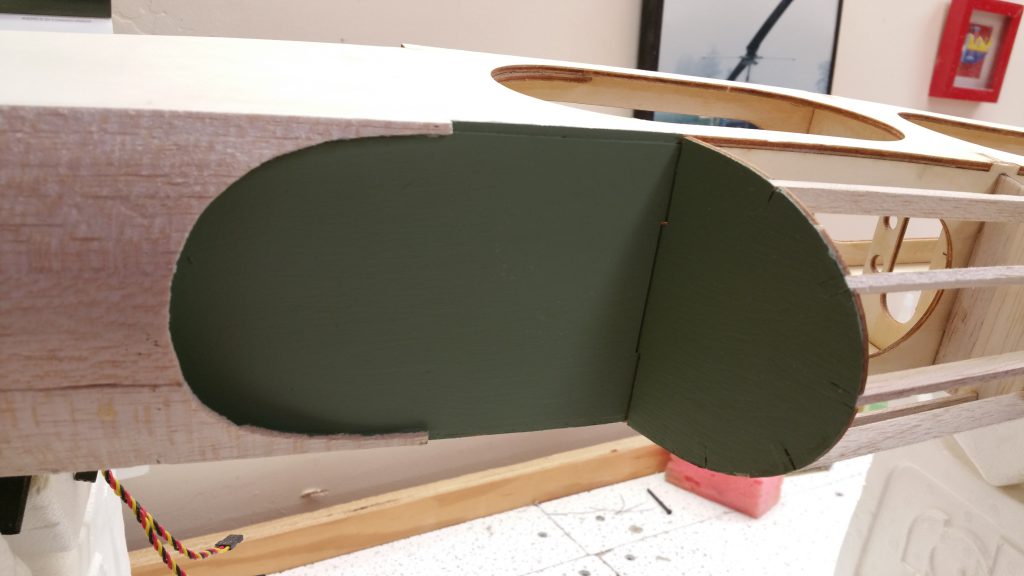

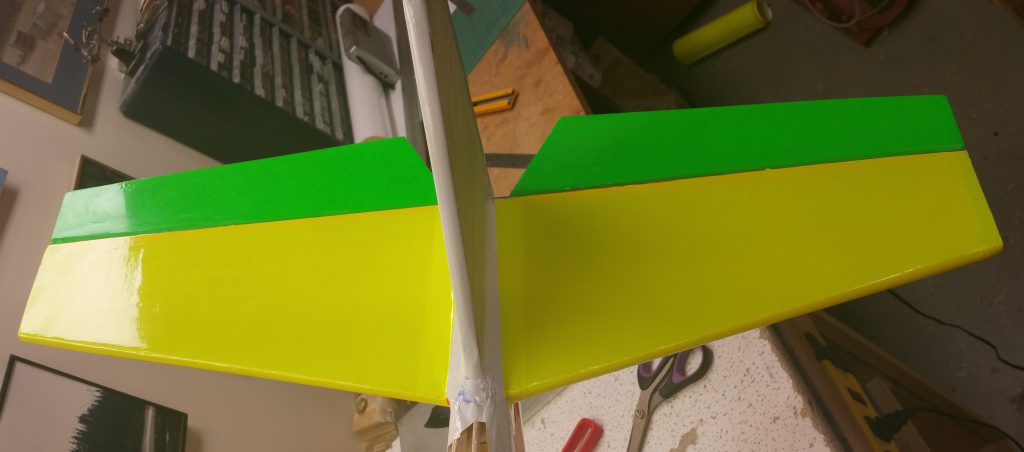

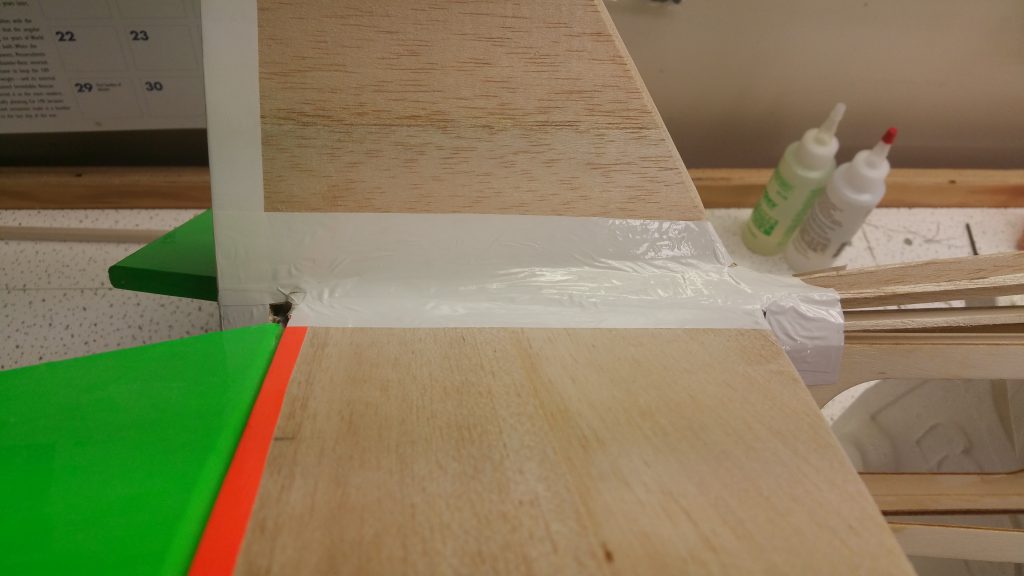

On Saturday I got to work on my plane again and made some more progress on covering and installation of the fuel tank. One of the discussion Peter & I had in a previous session was what I’d like to do with the cockpit, use covering or paint it. I decided to go with painting […]

Building 4 Star 60 Day 37: Covering, Fuel Tank and Rudder Hinged Read More »