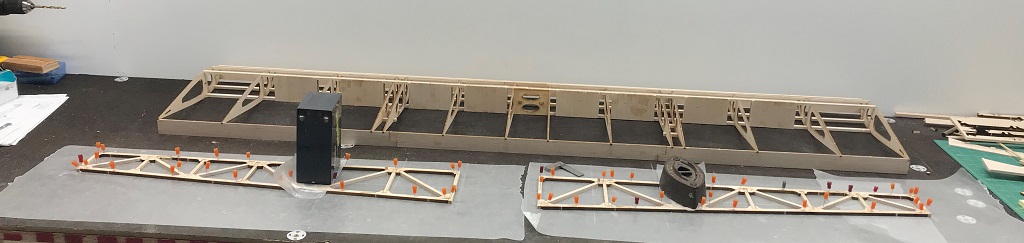

Building Aero 3D Day 31: Sheeting Wing Begins

Wednesday we started the process of sheeting the wing. Prior to actually sheeting we went over the whole wing doing some sanding, removing any excess glue gobs, rough edges, etc. making sure everything was finished as best we could. This is to make sure the sheeting sits down properly and eliminate as many covering issues/bumps […]

Building Aero 3D Day 31: Sheeting Wing Begins Read More »