Building Seamaster Day 61: Tank Fit & Power Switch

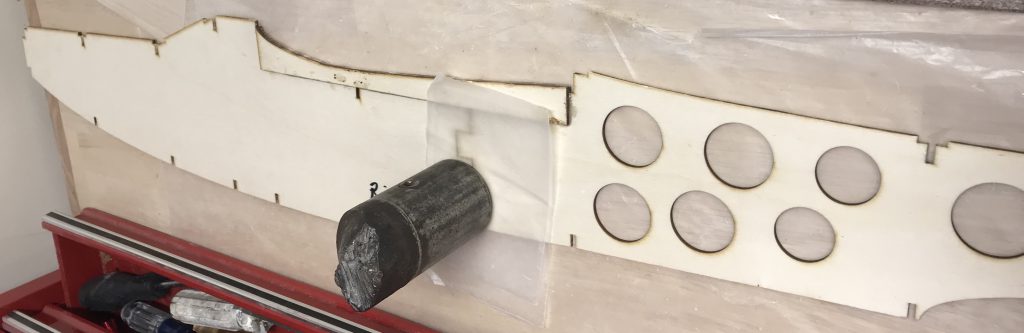

We were having an issue with getting the tank to fit in the fiber-glass housing along with some foam for protection to prevent it from raddling around. On May 11th I did a trial fit of the tank, with the foam stuffed in, now that the engine is mounted, painted, etc. to make sure things […]

Building Seamaster Day 61: Tank Fit & Power Switch Read More »