Monday the 19th was a day of dang’s and backtracking before nicely getting ahead. When I first got there and was working discovered that the sides of the fuselage hadn’t stuck together well enough. Bad batch of glue! That’s my story and I’m sticking to it… the only other evidence I have is that Peter tossed both parts for mixing it up and the fact they didn’t stick.

To rectify the sides coming apart I had to re-glue it (seen above) and thankfully this time it stuck! Same process as before (without all the sanding), but unfortunately means not as much progress was made this day. Also did a lot of sanding (John helped as well) due to the excess glue around the top of the doubler as you want to make sure the wing will sit nicely within the ‘saddle’.

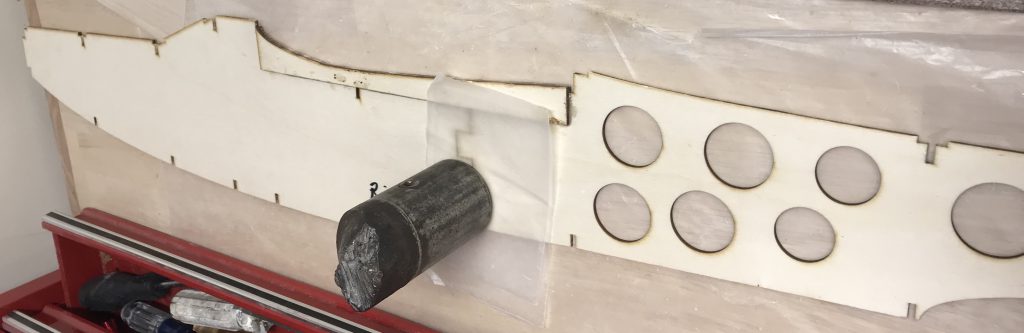

What was suppose to be the main focus of this session was building the pylon, pictured below. This is the main support for the fuselage and the engine mount (that will be above the aircraft mounted onto the piece of wood sticking out, plus other pieces I’ll get to later in the build).

For this I had to find the 4 pieces that make up the pylon (two of them are formers, F4 & F5). The front is the smaller of the formers. I then went to sanding the sides of all the pieces, followed by gluing the pieces that will help hold the main support for the engine (or so I’ll call it) and complete the pylon connecting F4 & F5.

That was it for this day as needed to wait for everything to dry before proceeding. Also to make sure everything stuck together properly as well!