Building Aero 3D Day 58: Hinging Wing & Ailerons

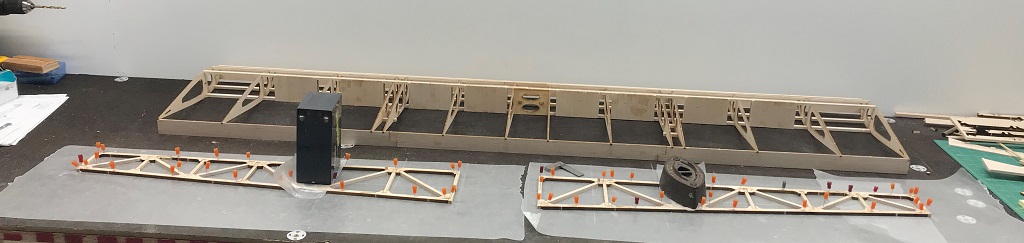

Thursday, I got my hands on the hinging tool again, and this time it worked! Started by verifying the hinge locations and making clear center marking on both the wing and ailerons… verifying we were using the correct aileron for the side we were working with. Once that was done used a centering tool to […]

Building Aero 3D Day 58: Hinging Wing & Ailerons Read More »