Building Aero 3D Day 69: Push Rod & Elevator Linkage

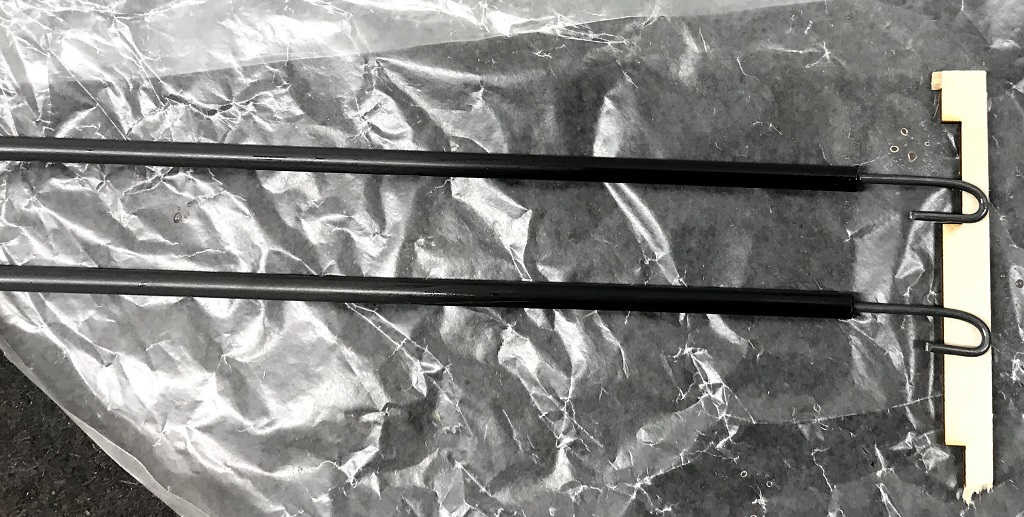

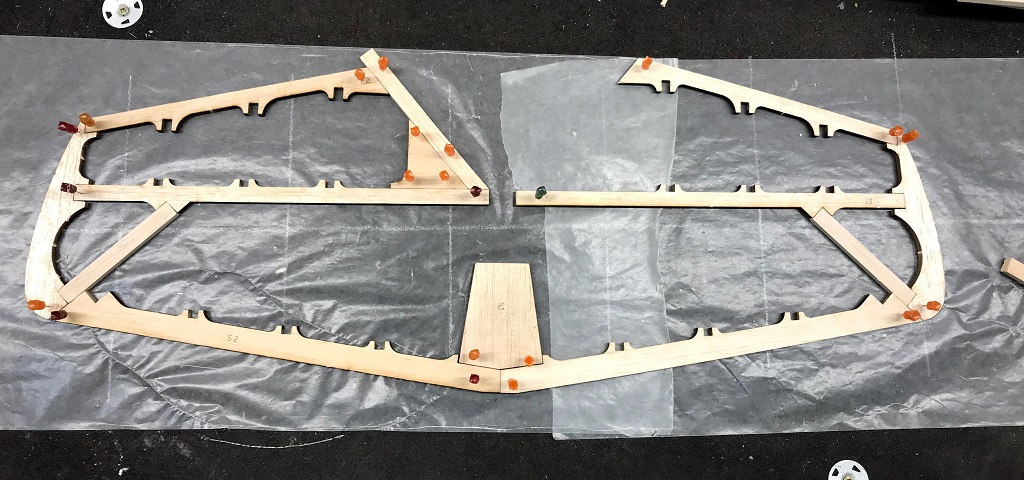

On Nov. 11th made some more progress. Started with unboxing and getting 3 servos ready. For the two heavy duty control surfaces (elevator & rudder) using HiTech HS-645MG servos and for the throttle that doesn’t undergo the same amount of force a HiTech HS-425BB servo. For putting the control horns on figured out where each […]

Building Aero 3D Day 69: Push Rod & Elevator Linkage Read More »