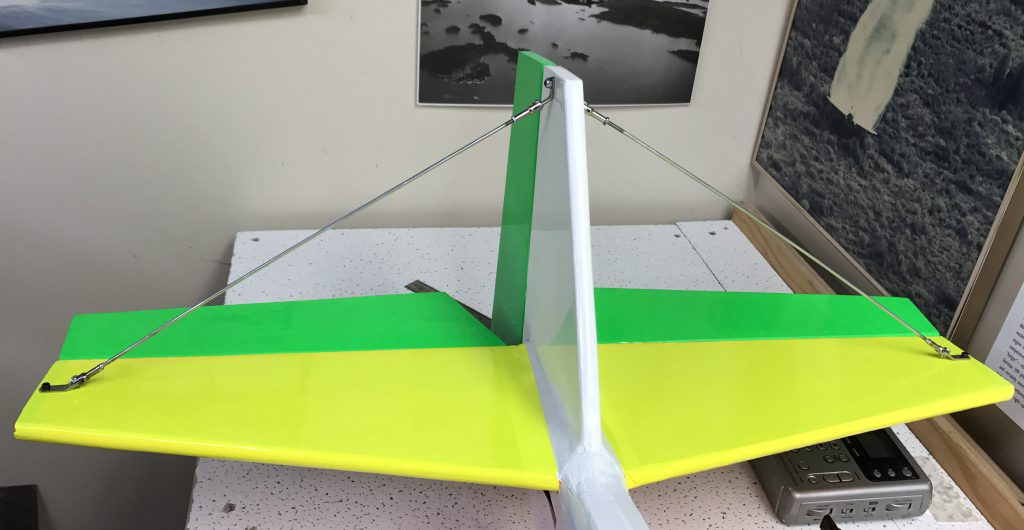

Building Aero 3D Day 67: Fin Glued

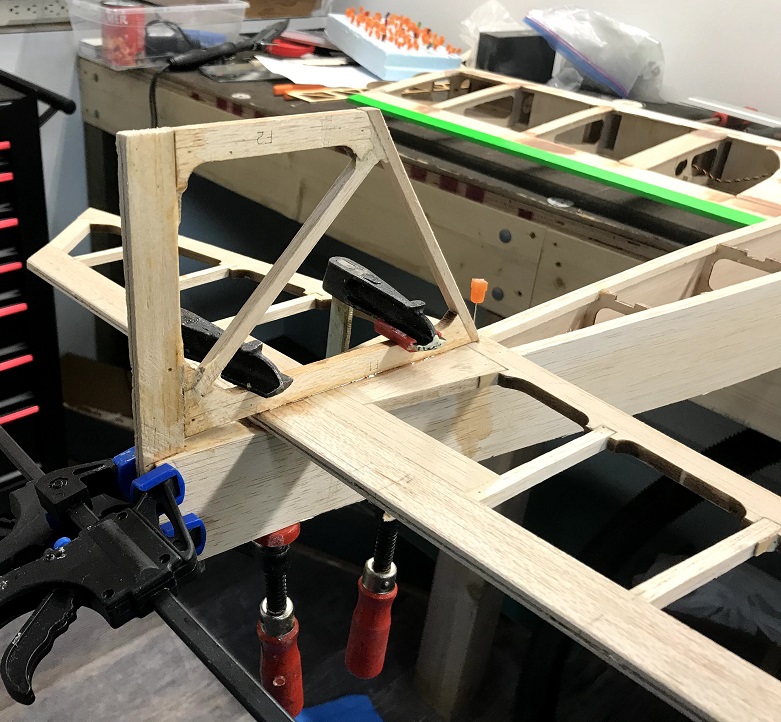

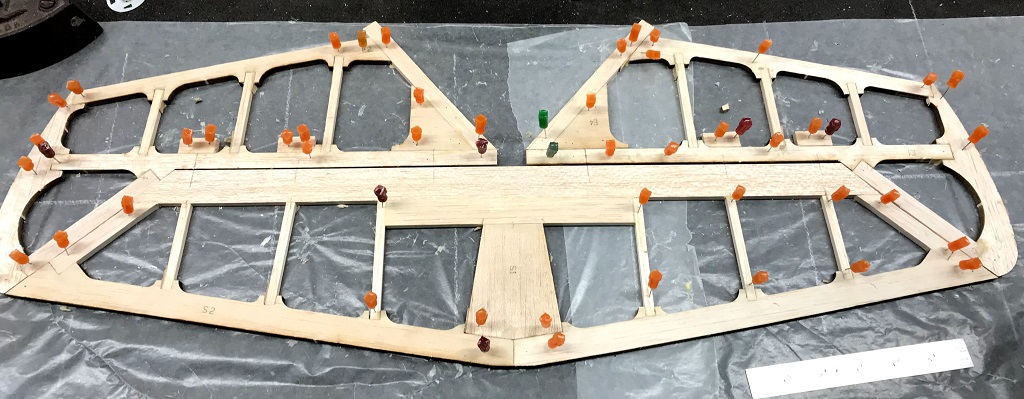

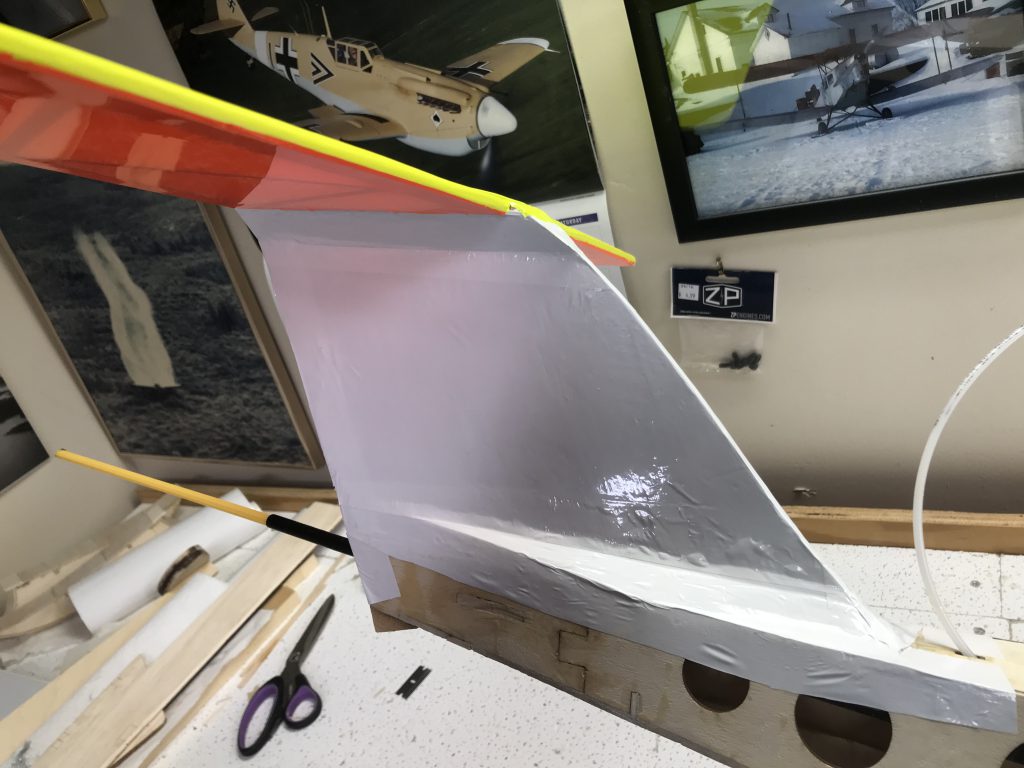

Yesterday, did some more work on the Aero 3D. In the previous session looked at how the fin would go on and discovered I previously chopped off a piece of the trailing edge that I shouldn’t have. I was wondering how the fin would remain stable on the fuselage and this was in part due […]

Building Aero 3D Day 67: Fin Glued Read More »