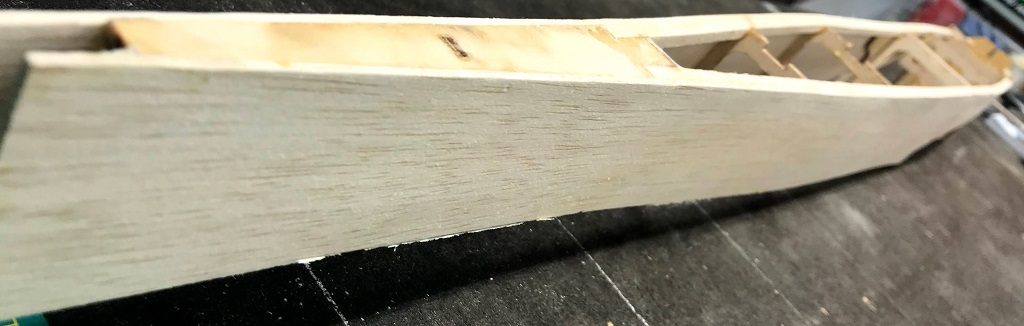

Building Aero3D Day 70 & 71: Push Rods and Rudder Hinges

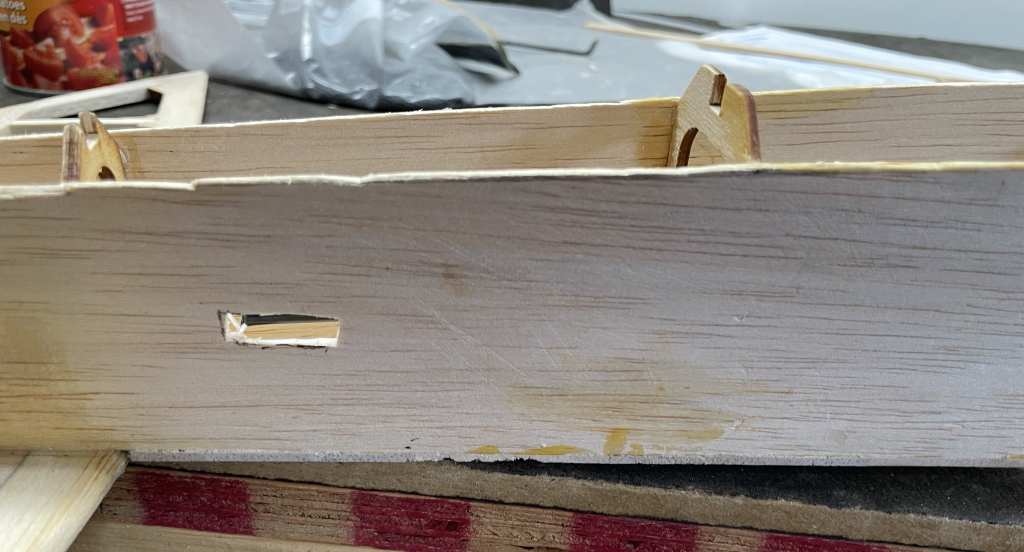

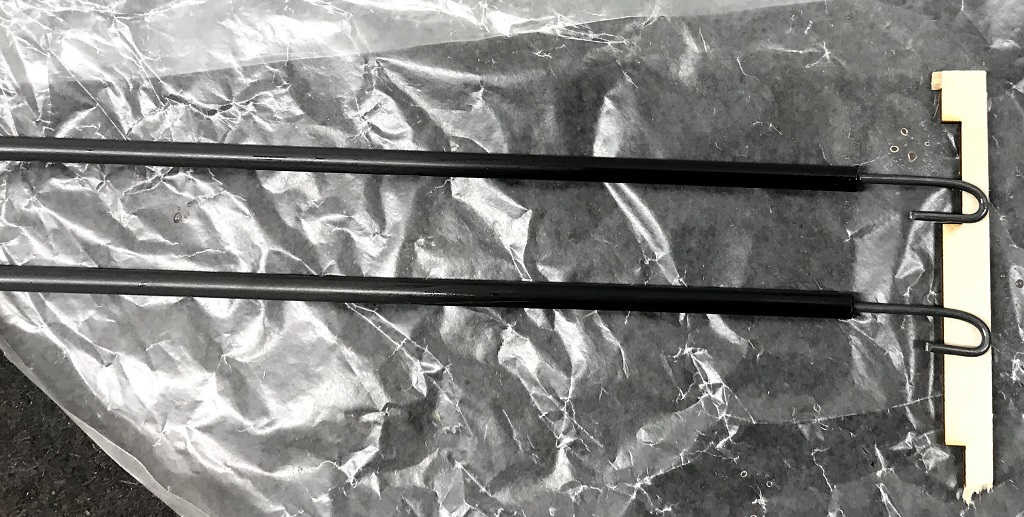

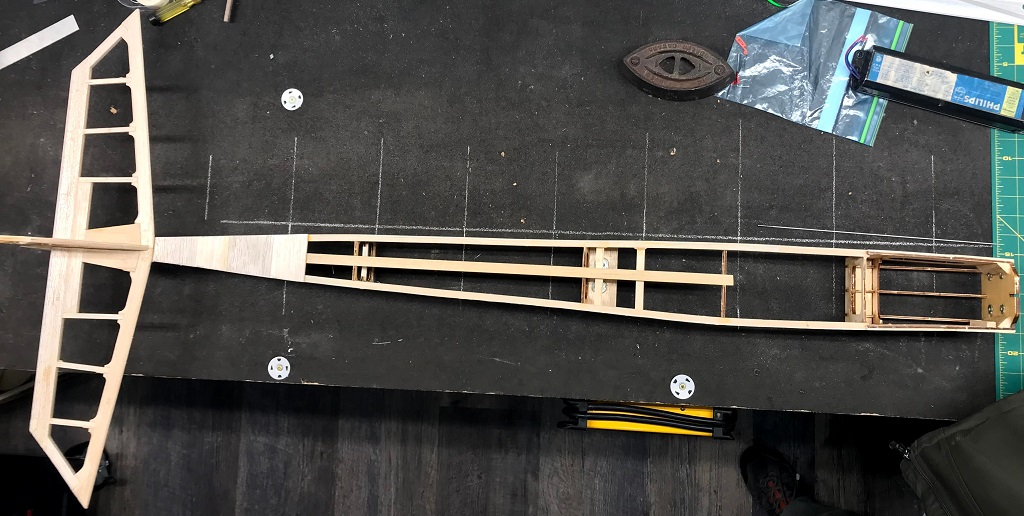

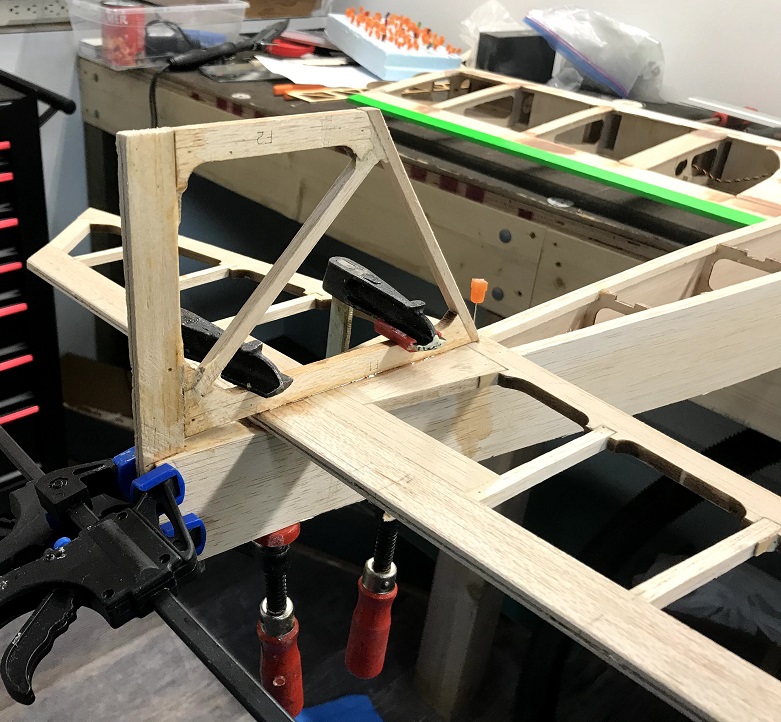

Last Sunday Peter came over and we re-orientated ourself to my Aero 3D building project. It has been a long time since last working on it! After discovering where we left off we got the elevator push rod slot made and cut down to size (exciting to use my Dremmel). Took quite a bit of […]

Building Aero3D Day 70 & 71: Push Rods and Rudder Hinges Read More »