Building Aero 3D Day 60: Wing Bottom Filler

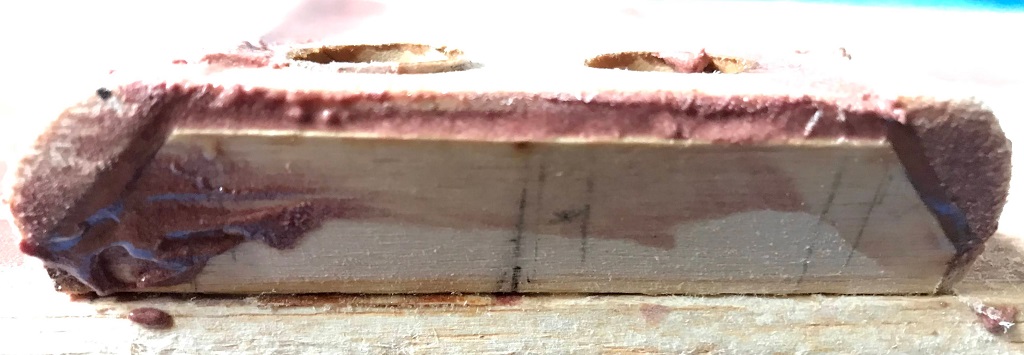

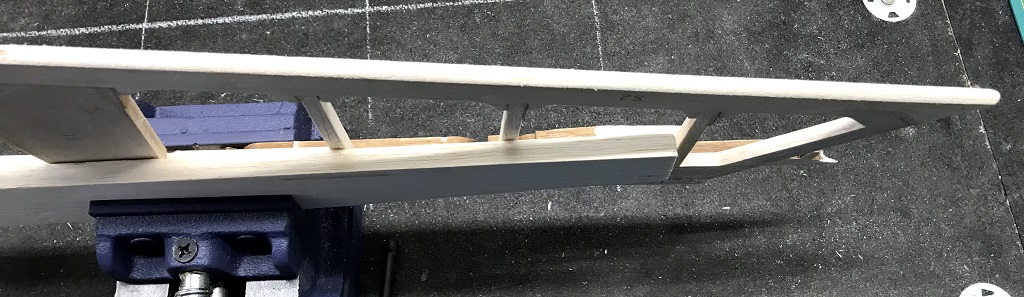

Thursday, Peter brought over his epoxy and filler powder so I could mix up a batch and smoothen out the surfaces on the bottom of the wing. First, finished sanding the W-ST-2’s to be as flush as we could to the W-SH-6 sheet. Then using a popsical stick I applied the filler thick and Peter …