On Nov. 6th I finished covering the bottom of the wing by cutting two pieces to fit down the center, seen below. The first wraps around the leading edge of the wing and goes down to the edge protrusion and the other goes from bottom of the protrusion to the trailing edge where it was trimmed off to be flush with the edge. This completed covering of the bottom of the wing.

After that, I started work on the top of the wing by doing the piece going down the center, seen below. I also got the covering for each wing panel cut this day as well.

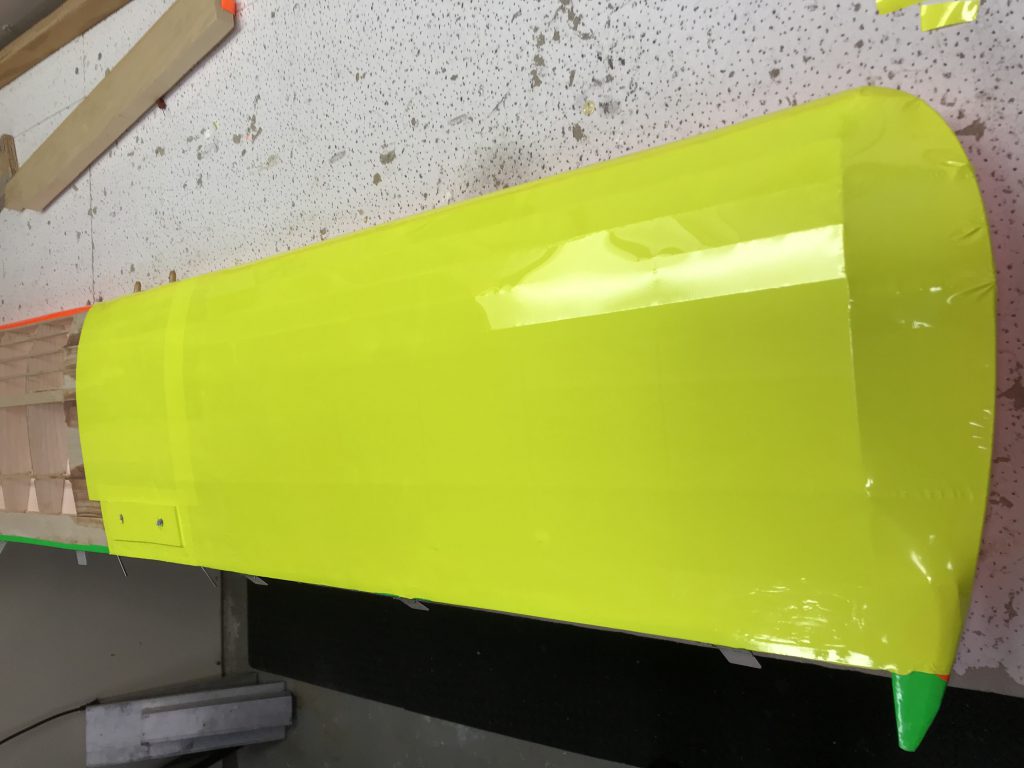

The next time, Nov 7th, I spent a couple hours covering the top left panel of the wing, seen at the top of this post. In order to do this I followed a very similar process to what I did for the bottom. The only difference comes to when wrapping around the wing tip I cannot fold it over onto the wood. Instead I did cuts accordingly and ironed it to the very thing wing tip outer edge. I then did my best to cut the covering along the edge as neatly as possible.

My one concern is how everything is wiring up as I have run nothing prior to covering and am taking Peters word that it is going according to plan since I have had nothing ‘official’ to look at and follow along the way. My best guess is that the servo is going to mount into the bottom of the wing somehow and the push rods are going to go along the outside of the wing for controlling the ailerons. Perhaps this is to help ensure no water gets in and a better seal between the wing and fuselage?