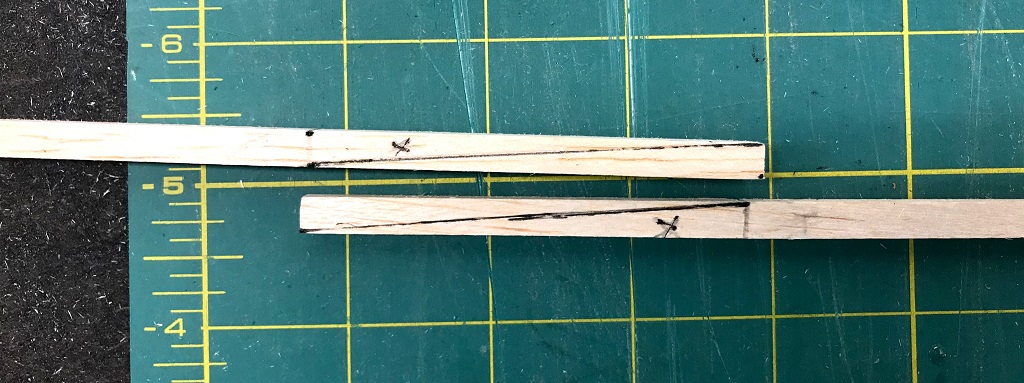

Building Aero 3D Day 38: Trailing Edge

Wednesday, Peter came over and we made some more progress. Could only do a little bit as the trailing edge is required to continue. First, using a forstner drill bit, I drilled a hole into the top center of the wing. Peter held a piece of ply behind to help prevent the balsa sheeting from […]

Building Aero 3D Day 38: Trailing Edge Read More »