Building Aero 3D Day 51: Bolt Holes & WF Assembly

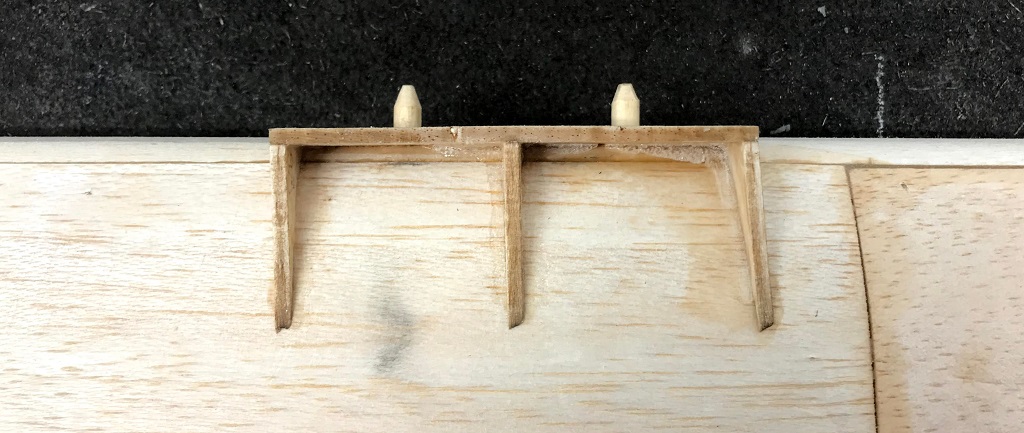

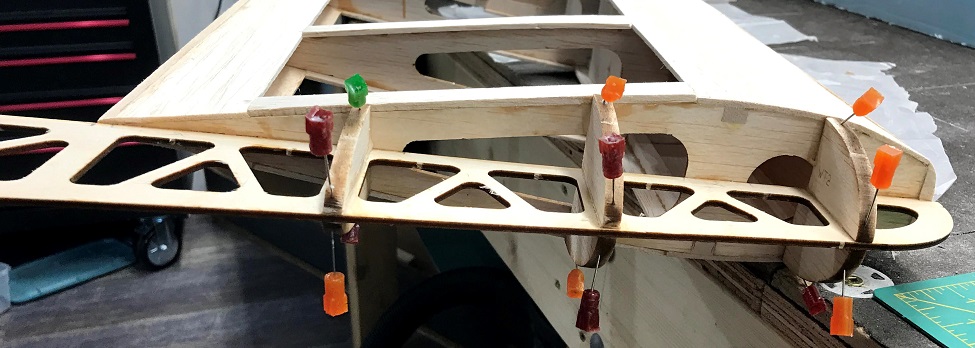

Yesterday afternoon I made minor progress on the aircraft. I started by continuing with work on the wing. I marked the center between the outter and inner WDs on the previously marked line indicating where the wing lines up on the center of the ply wing bolt plate in the fuselage. I also cut 1/4” …

Building Aero 3D Day 51: Bolt Holes & WF Assembly Read More »