Building Seamaster Day 4: Pylon and Side Meet

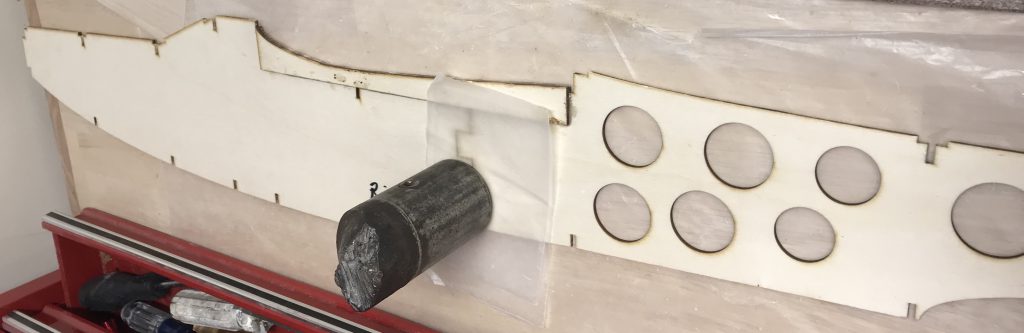

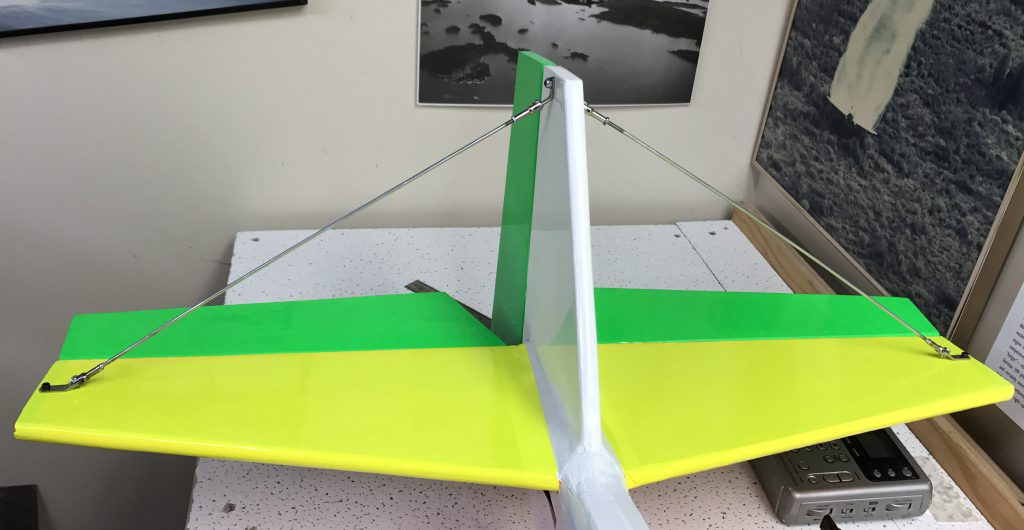

February 21st was about finishing off the Pylon and starting to get the fuselage sides attached. The first step was ensuring the seems of where the spacers meet the formers are secure by applying a bead of medium CA glue long the seems. This was done for all four areas, inside and out, making for …