Building Aero 3D Day 54: Figuring Out WC Assembly

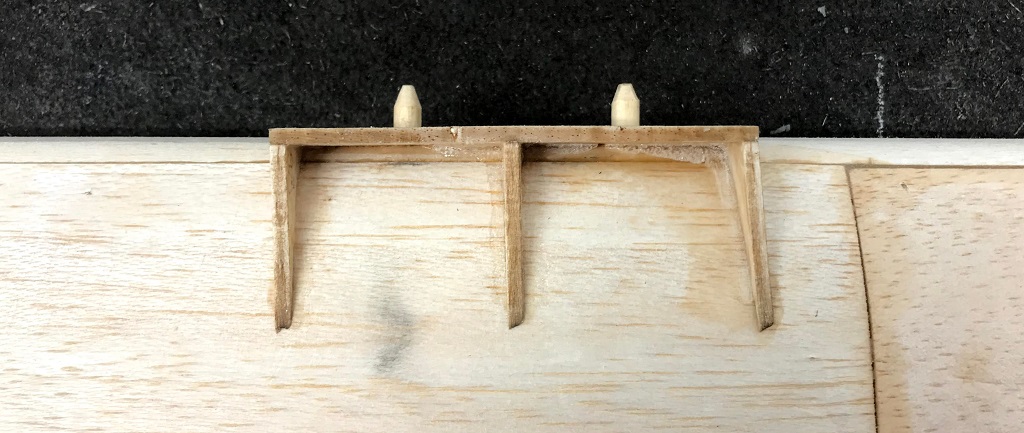

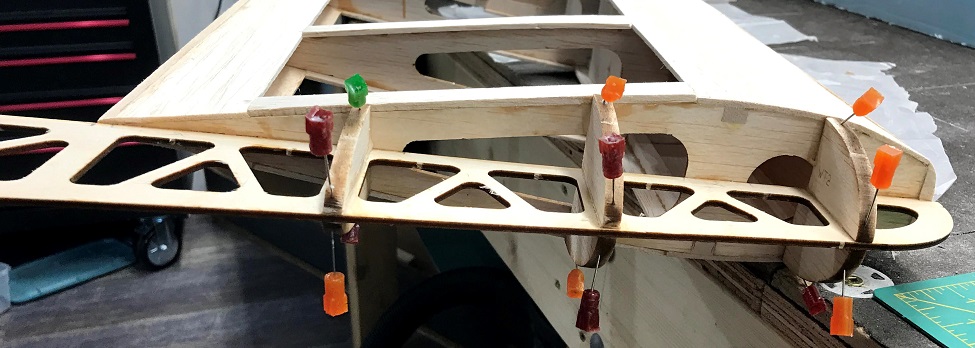

Saturday, I experiemented with how to build the rounded edge (W-ST-2s) pieces for the WC assembly… which is what I’m calling the group of pieces that congregate around the bolt hole openings on the bottom of the wing.