A Not So Takeoff Takeoff

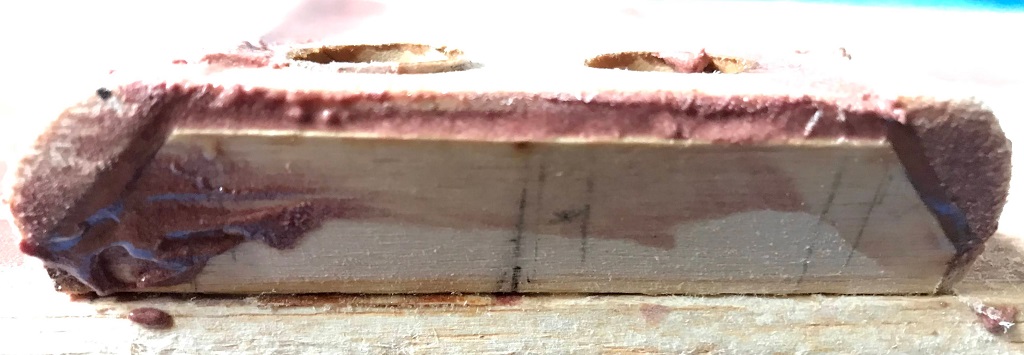

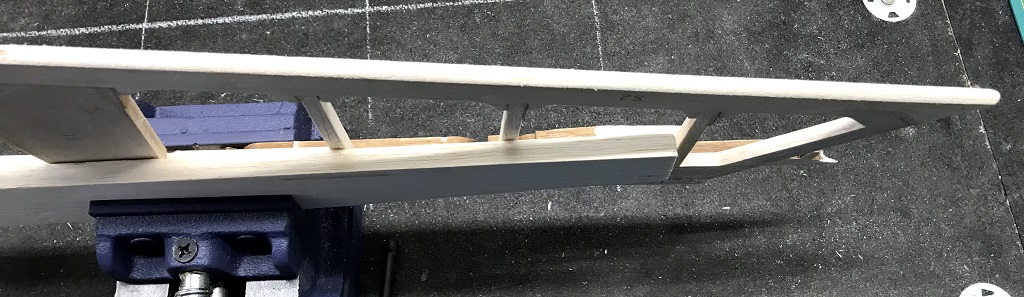

June 24th I got out flying, finally, after quite a hiatus due to inclement weather. The days events didn’t go as planned to say the least. The following is an account of what happened that day after I had some time to organize my thoughts and go over things in my head. When I first …