June 15th was about water-proofing the cradle in the fuselage for the wing. This involved using a cocking gun to apply silicone all along the top edge of the cradle in the fuselage (where the wing sits) and making sure to place lots up under the ‘water-deflector‘.

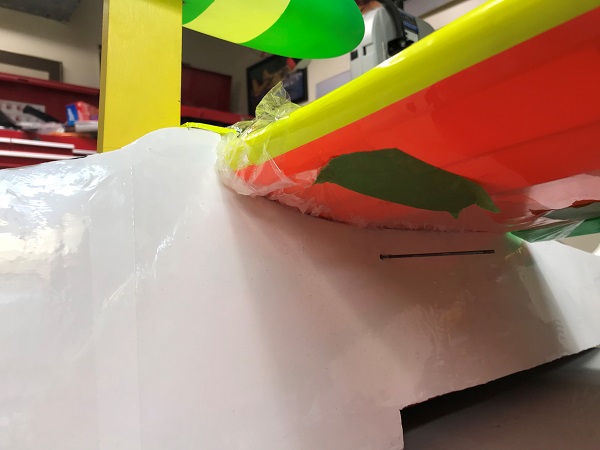

To prep for this job I wrapped some seran around the front center of the wing and taped it in place to prevent silicone from getting onto (and drying) to the covering of the wing. Teh wing is assembled on the fuselage during the drying process to make sure that the silicone forms properly to how the wing needs to fit and a tight seal is made.

Unfortunately during this process (we didn’t test the wing installment first as hasn’t been tested since installing the ‘water-deflector’) we realized the wing didn’t fit on the fuselage anymore and had to use the dremel tool to shorten the backside of the deflector, which will have to be covered again (since wood on the back edge is now exposed) , to get everything to fit correctly.

You can now really see the aircraft coming together in the image below:

Below you can see what it looks like from underneath. The seran taped into place and the wing sitting in the siliconed craddle.